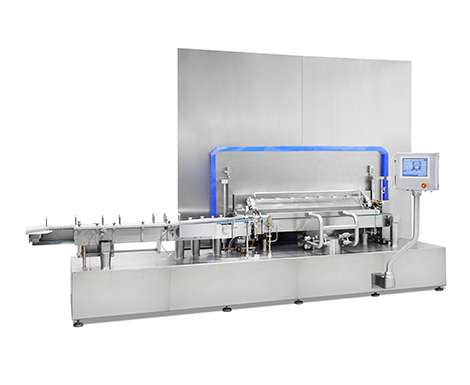

GMP Freeze Dryers and Loading Systems

Backed by more than 60 years of experience as manufacturers of freeze-dryers, the Telstar family has become a trusted supplier for the global pharmaceutical industry.

The purpose of our commitment to continuous improvement is excellence: we have our own R&D department, and we collaborate with the main suppliers of filling lines in “turnkey” projects. Therefore, at Telstar we can offer infinite advantages in the pharmaceutical lyophilization sector and act as an integral partner.