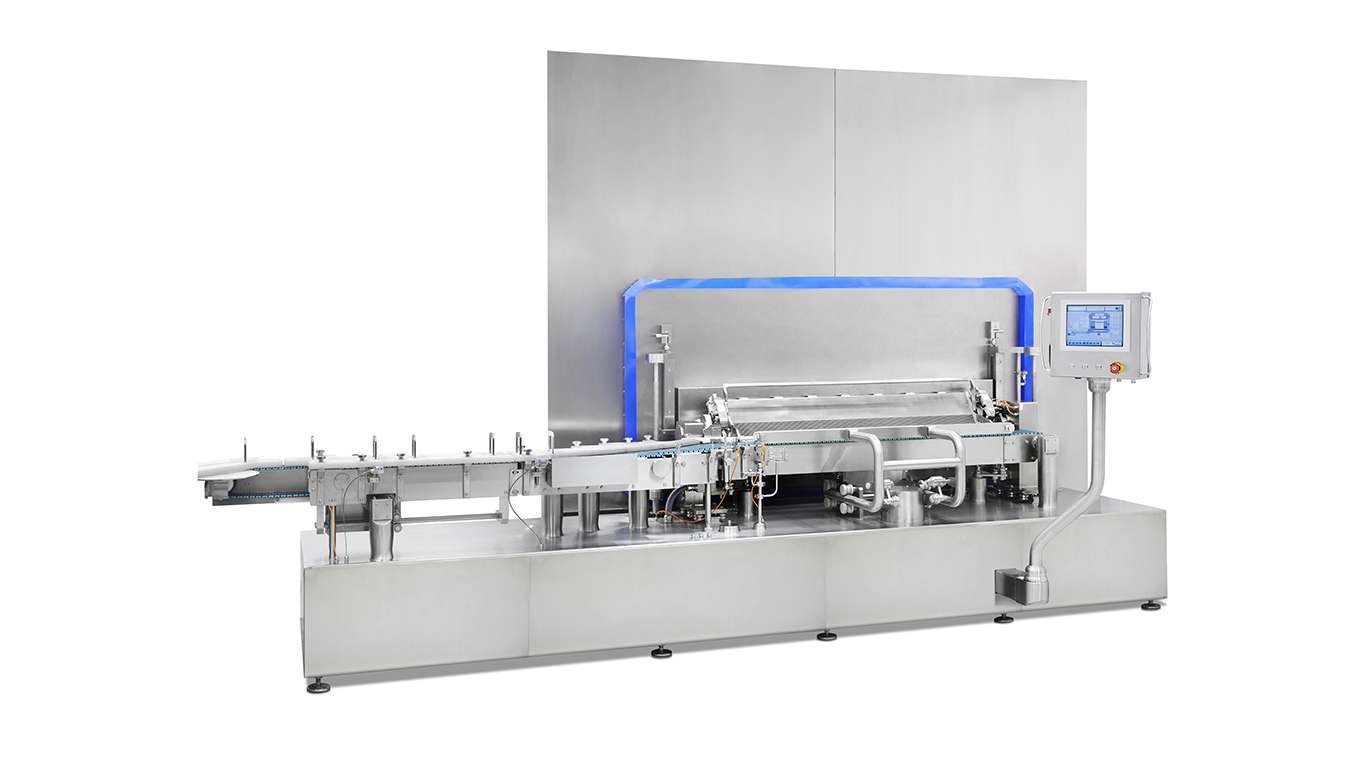

GMP Loading and Unloading Systems

Lyogistics

At Telstar we understand that each freeze-drying application is unique. For this reason, we have the Lyogistics range: a family of loading and unloading solutions, designed to satisfy all viable options. We offer manual, semi-automatic and fully automatic systems for vials and bulk product (trays, Lyoguards®, etc.). All can be easily integrated with isolators or RABs